BDF swap body systems are, by definition, a simple and versatile solution. Is there a way to make them even more user-friendly?

The second decade of the 21st century – and in particular its final years – brought with it intensive development of new technologies in the field of truck transport. We are on the threshold of a new era, in which worn-out diesel engines are gradually being replaced by alternatives such as LNG fuels and electric motors.

A revolution is also taking place in the way the cargo is transported. We have repeatedly described the advantages of BDF systems and intermodal transport on our blog. They are gradually changing the face of modern logistics on the European continent. This flexible solution makes it possible to significantly simplify the entire logistics process. Not surprisingly, many hauliers are considering introducing them in their own businesses.

What are the challenges of introducing BDF systems?

The implementation of swap body systems may bring many benefits to the company. However, it requires the knowledge necessary for their correct implementation. Many companies entering the BDF sector do not have the experience needed to use their full potential. No wonder – it is still a relatively unknown product, and learning it in such companies is often done by trial and error.

Another challenge with BDF systems is the question of how to fit them into the equipment you already have. Commercially available solutions may, depending on the manufacturer, differ in technical specifications and may not be usable in particular configurations. The problem arises when you use chassis from different manufacturers or vehicles running on different types of fuel.

Universal Swap Body

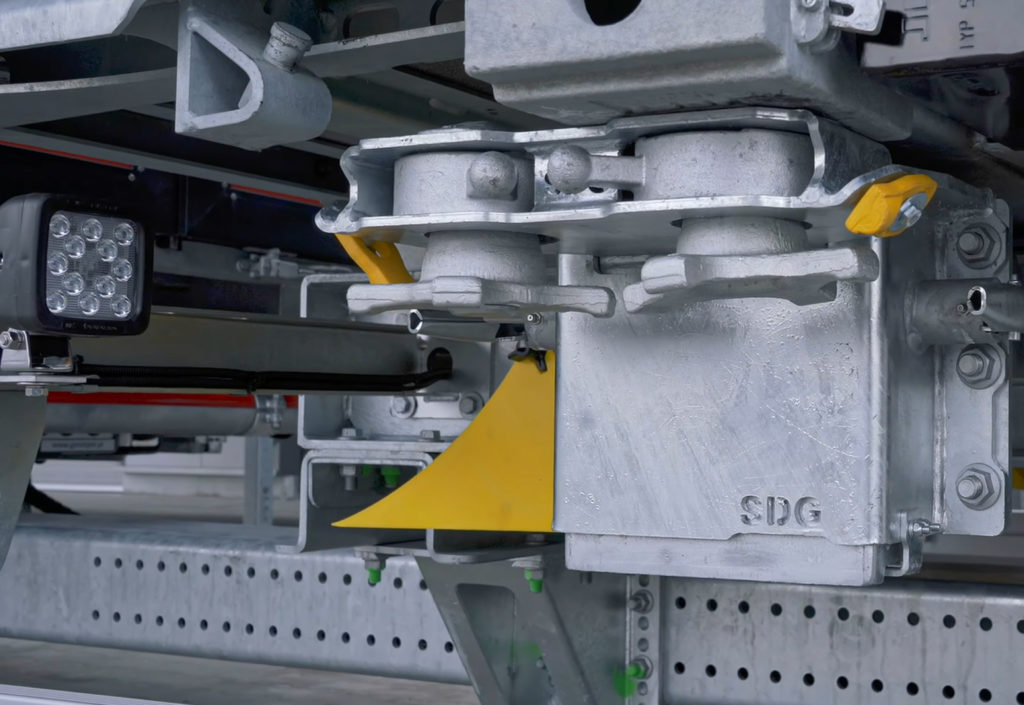

The answer to the potential challenges of implementing BDF systems is the innovative KHV swap frame. It was launched in September 2020 at the internal trade fair of our partner, the German company SDG. The solution patented by SDG Modultechnik takes the BDF concept to a new level of versatility.

The hot-dip galvanised steel frame construction put versatility first and ease of use, both for the manufacturer of bodies and the user. What is important, installation of the KHV frame is possible on all truck chassis. It requires no space below the main chassis frame. This makes it possible to use the maximum size of fuel tanks (both diesel and LNG) while maintaining an adjustable stand-off height from 1120 mm to 1320 mm.

Ultimately, the KHV frame allows up to 80% of the bodies in the courier segment to be handled. For companies requiring even greater flexibility, HVC heads are used, making the combination even more versatile by extending the range of stand-off heights.

Easy to Handle Transport

In addition to its versatility, the HVC KHV swap frame also features easy handling and a high level of safety. Hot-dip galvanisation ensures excellent corrosion protection for many years. The support points for the second support height level (which also act as guide rollers) and the low weight of the components mean that the support height can be changed quickly in just over a minute.

Solution for Beginners and Experts

These improvements make the BDF systems based on the KHV design the ideal choice for both newcomers to the technology and experienced hauliers who appreciate comprehensive solutions. In the first case, they allow a model for handling swap bodies to be tested in its most user-friendly version. Thanks to the KHV frame, the driver will be able to learn new skills quickly.

For companies familiar with the BDF sector, this is a solution that focuses mainly on versatility. The ability to adapt the frame to a chassis from different manufacturers and powered by several types of fuel (or electric motors) allows the swap-body systems to be adapted to many vehicles in the fleet.

On the Road to Simple Transport

From a global perspective, solutions such as KHV contribute to the popularisation of BDF systems and intermodal transport. The benefits of this trend will definitely be visible in many aspects of our lives. These solutions offer a socially responsible alternative to traditional truck transport. For businesses, on the other hand, it is a sensible solution from the point of view of managing the entire logistics process.